Wearable Body Sensors to Be Ameliorated Using Silk

Smart wearables are the latest trend nowadays. The people are using the technology to such an extent so as to measure the slightest of the changes in their body and keep their health fit and fine. This is currently becoming a must have technology. The technologies are being built in from socks to clothes. The world’s most coveted fabric silk is what the scientists are looking forward to utilize so as to make a flexible and sensitive device for multi-purposes such as monitoring body functions in real time.

The silk is a material that can prove ideal at the moment as the wearable technology has to be worn on the body. The overall possibility of using it has increased. There is an advantage that the material can be used as an integrated wireless system so as to make it easier for the doctors to track the patients’ changes remotely and understand their response to the medical needs more quickly.

Generally, the semiconductors are used to develop the body sensors as they possess a lot of potentials to monitor the human health conditions more precisely. However, the material possesses certain limitations. For instance, in case of strain sensors that are designed to measure force, it is highly impossible to act as a sensitive and stretchable material at the same time. Thus, here is where silk, a natural material, can come into play as it is stronger than steel and flexible than nylon. The natural material can help overcome all the problems normally faced in the semiconductor built sensors, as they are biocompatible and light in weight too.

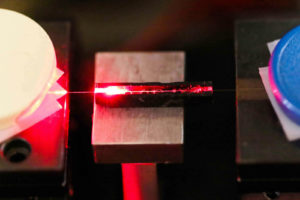

One drawback is that silk is a bad conductor of electricity. Hence, the scientists Zhang and his team from Tsinghua University have found out a solution to make silk conductive and further be used in the body-sensing devices. For making silk conductive, the researchers used two methods. Firstly, they treated the material in an inert gas environment with temperature ranging from 1,112° to 5,432° Fahrenheit. Thus, the silk was infused with N-doped carbon and graphitized particles making it electrically conductive. The silk was used to create strain sensors, pressure sensors, and dual-mode sensors for monitoring pressure and temperature, respectively.

In the second method, the researchers are feeding the silkworms with carbon nanotubes and graphene in order to produce naturally incorporated nanoparticles material. The researchers are still experimenting with this technique till a thorough result is obtained. The team is exploring means to develop an integrated silk-based and self-sustaining sensor that can be powered by nanogenerators. After which, the developed sensors can be used to create realistic robots that can feel and sense things.

For now, the team has just presented its work at the 254th National Meeting & Exposition of the American Chemical Society.